Conveyors: Everbesten can design and manufacture products which can guarantee the stability of the product's movement and the efficiency of the lines.

Bottle conveyor belt: Handle product with a smooth operation and flexible adjustments.

Good and flexible designs can guarantee the movement of the product complying with key machine conditions. Combine/diverter equipment are applied at high speed .without damaging or dropping the product's movement.

Pressure less conveyors:

The most advanced control concept. Less pressure among bottles, less strike, more reliable , higher efficiency.Less bottle dropping.More and more pressure less conveyors are applied on the production lines to meet the requirements of higher speed and lighter weight bottles.

Divider:

Widely applicable to single pass double or multi conveyor belts

Especially suitable for square or lightweight bottles

Characteristics:

Used at the entrance of the baler to reduce damage to the bottle

The servo motor is used for the bottle to make the bottle direction smoother and softer.

Reduce the risk of bottle down and greatly reduce the damage to the bottle

Type of bottle separator:

1 minute 2, for round bottles, square bottles and rectangular bottles

1 minute 6 or 1 minute 8, speed can reach 66000 bottles / hour

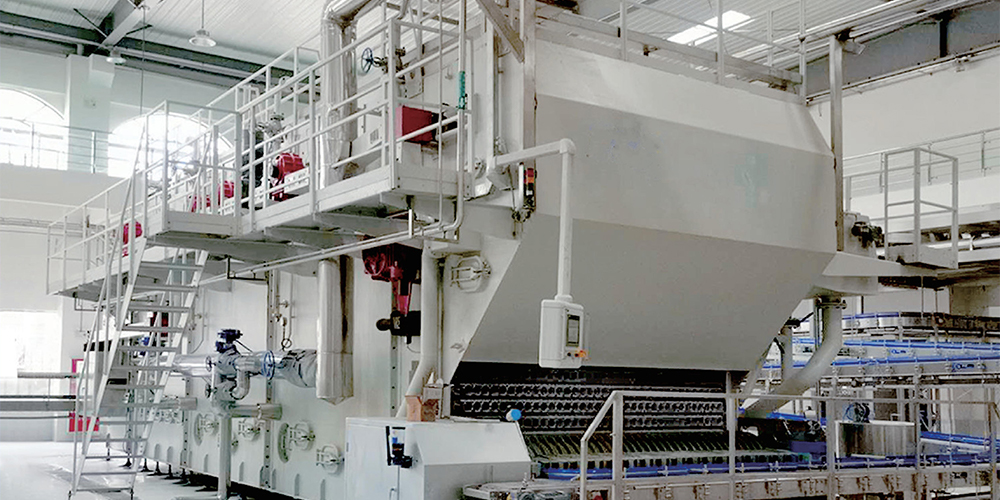

Equipment composition:

Import and export frame, up and down skateboard accumulation area

Implementation function:

When the speed of imports and exports changes, Keep the conveying material inside the equipment from squeezing or pull apart the spacing.

When imports are faster than exports, they accumulate.

When the import speed is slower than the export speed Drain the conveyor.

working principle:

The motor is driven by the plurality of motors to control the movement of the inlet and outlet and the middle of the conveyor chain. The detector detects the running speed of the inlet and outlet. When the running speed shows different states, the motor controlling the sliding plate drives the sliding plate to the stacking direction or the emptying direction.

Move until the limit point is reached, thus achieving dynamic buffering.

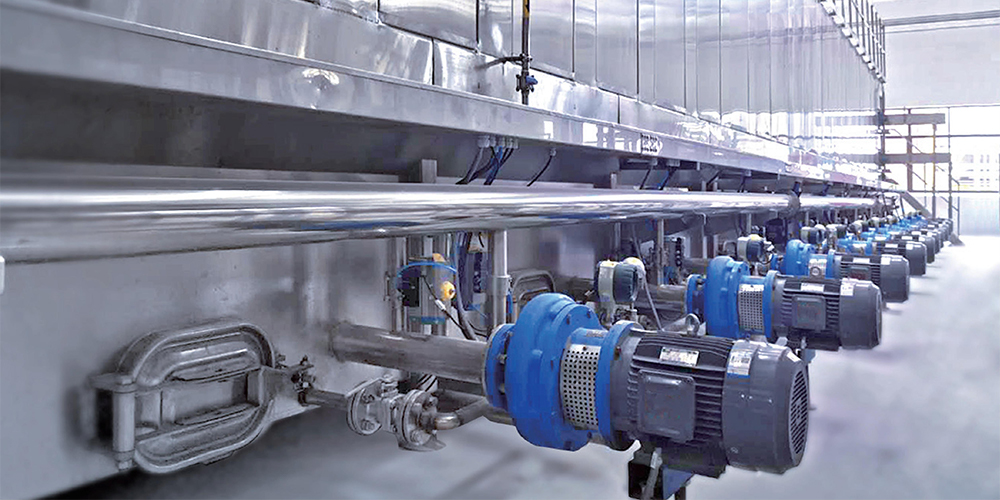

Air conveyor:

EAIR is specialized in the engineering, manufacturing and servicing of air conveyors, which can offer the complete competitive solutions for customers.

Convey light, empty, unstable bottles at high speed.

High flexibility with the connection between machines according to the customers requirements

Cleaned guarantee for sensitive products. As: ultra clean conveyors, sterile conveyors etc. High flexibility and multi-size bottles

The air conveyors are designed to suit different body/neck size bottles.

Special design for more difficult bottles.

Flexible equipment can combine and divide the bottles according to customers, needs, the lines are much more flexible and the investment is reduced.

Multiple filtration levels to purify the ambient air around bottles to meet the requirements for different products.

Side covers to protect the contaminated bottle from outside air, 2 face covers and

3 face covers are possible to be applied on these types of conveyors.

Preform conveying:

Mainly used for the transport of the preforms transported by the elevator to the bin in front of the bottle blowing machine. The bin equips full material and lack of material photoelectric to ensure continuity of subsequent production.

Cap conveying:

The top of the bottle cap conveying rail is provided with a detachable organic glass cover, Stainless steel dust cover is added to the cap warehouse. The cover can be opened locally to facilitate feeding.

The conveying active and passive sprocket is made of high strength nylon material, food grade chain board. The belt is provided with a protective cover, which is easy to be disassembled and assembled, firm and durable.